The "Smart Choice" for Drying Ovens

SELECTION

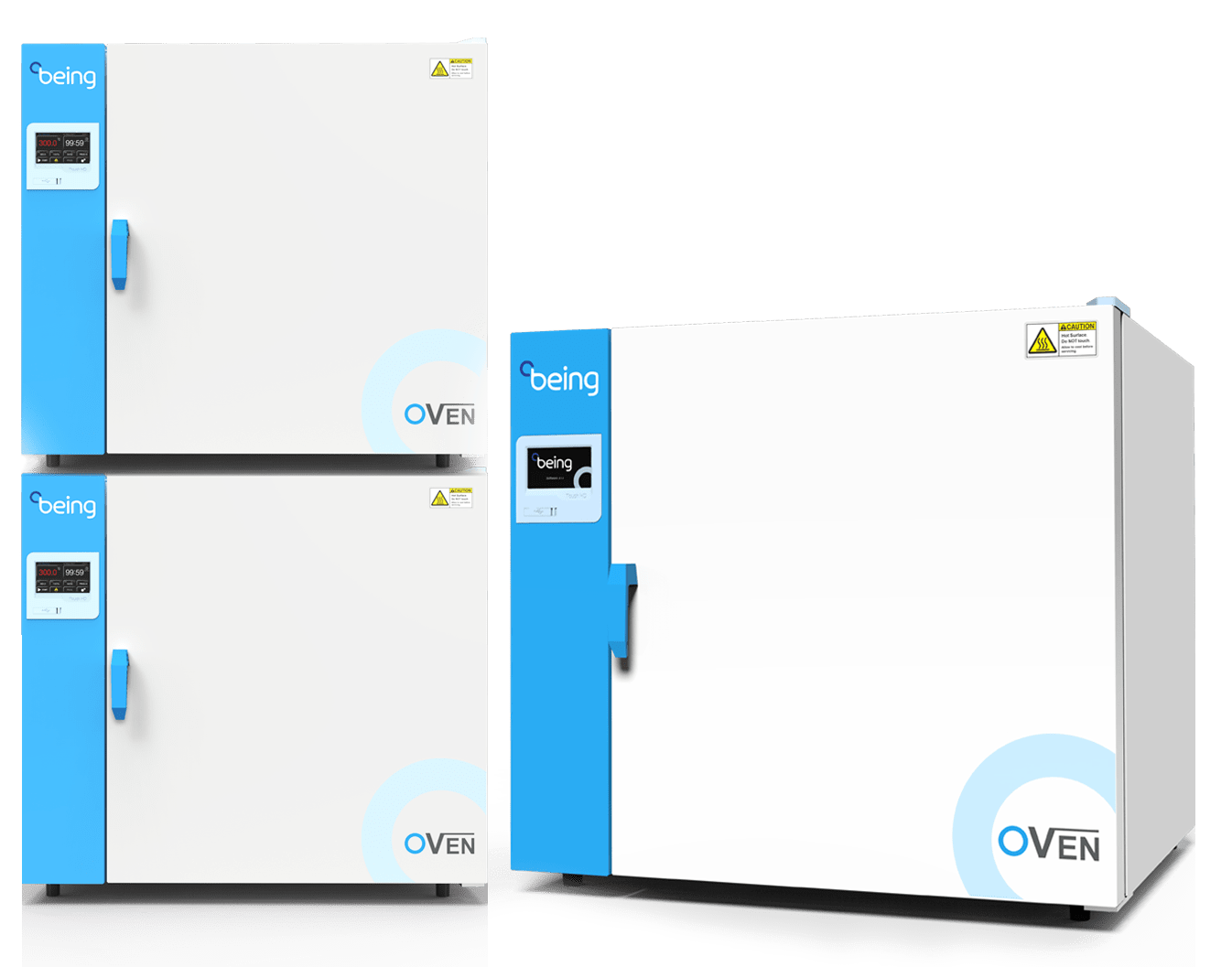

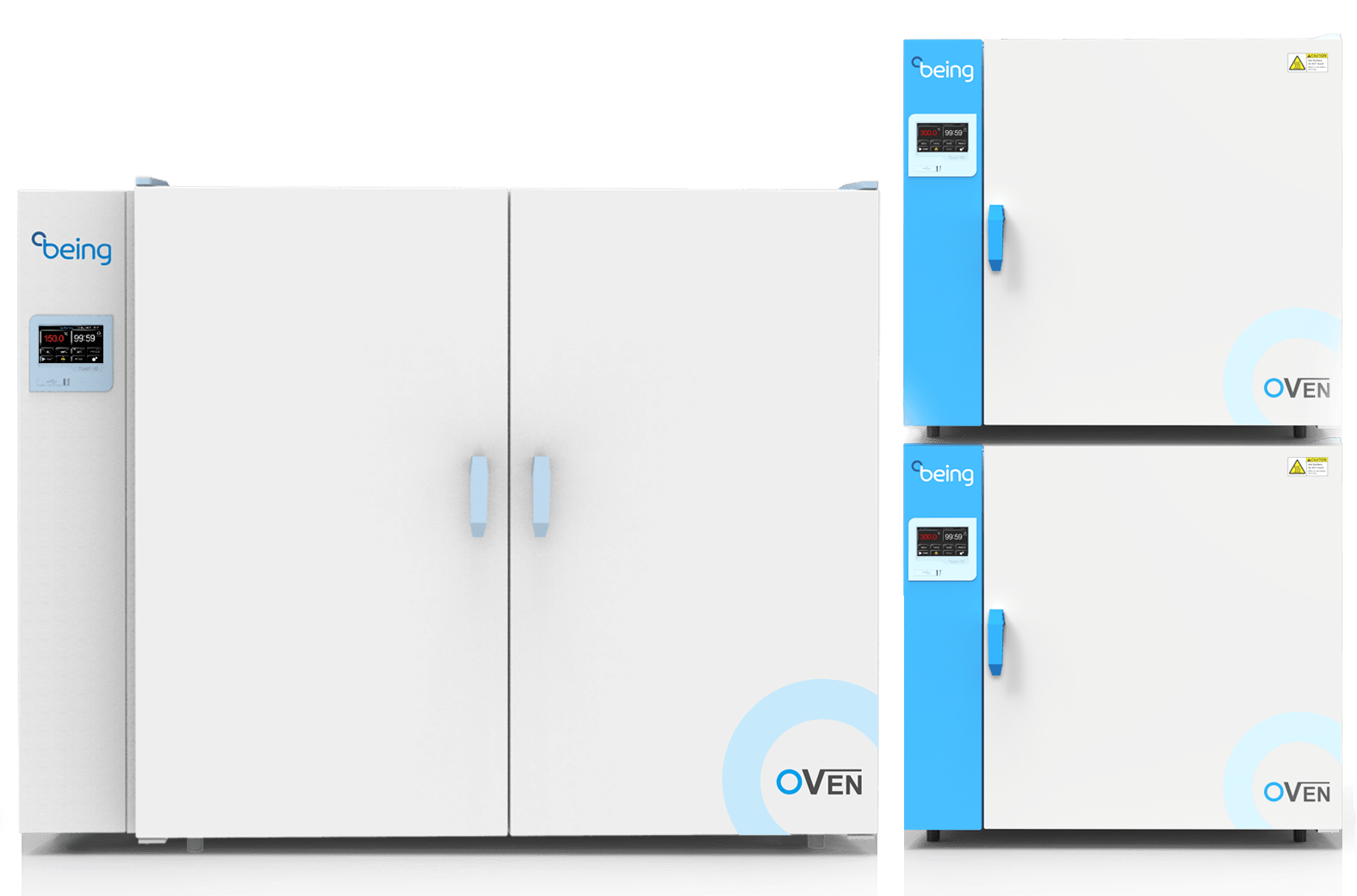

BOF Series

Mechanical Convection Ovens

The BOF Series mechanical (forced-air) convection ovens quietly and actively circulate air around the chamber, providing a stable, even, high-temperature (ambient + 300OC) environment with fast heat-up time for material testing and drying protocols and enable drying and disinfection of glassware, solid objects, solid materials, process equipment, and more.

These ovens are available in 5 sizes.

BOF-30T: 1.05 Cu. Ft. (30 L)

BOF-50T: 1.8 Cu. Ft. (51 L)

BOF-120T: 4.2 Cu. Ft. (121 L)

BOF-200T: 7.5 Cu. Ft. (211 L)

BOF-400T: 14.1 Cu. Ft. (400 L).

BON Series

Natural Convection Ovens

The BON Series natural convection ovens provide the same functionality as the BOF Series but do it naturally. The ovens use updraft technology to deliver gentle drying and heating with very low air turbulence to protect delicate samples, ideal for biotechnology, medical, research, or industrial environments.

These ovens are available in 4 sizes.

BON-30T: 1.1 Cu. Ft. (30 L)

BON-50T: 1.1 Cu. Ft. (30 L)

BON-115T: 1.1 Cu. Ft. (30 L)

BON-200T: 7.5 Cu. Ft. (211 L).

FEATURES

Ensuring efficient, safe, and easy operation

Intuitive Touchscreen Controller

The NEW 4.3-inch color, capacitive display ensures touch sensitivity and precision — even when wearing gloves. Set all the operating parameters quickly, simply, and intuitively thanks to user-friendly screens, icons, and symbols. Program a simple, fixed-value experiment or store 7 programs with 9 steps each from 1 minute to 99 hours 59 minutes.

The controller has 3 settings access levels: User, Service, and Admin. The service and admin-level menus are password protected to avoid accidental changes to “sensitive” parameters.

USB Data Collection

Insert a USB flash drive or cable into the oven’s controller before running your experiment. Select your fixed value or multistep program parameters. Press run, and the controller will automatically store the work cycle parameter data on your device at 1-minute intervals.

Stainless Steel Liner

Mirror-polished 304 stainless steel lines the BOF and BON’s chamber to provide excellent corrosion resistance. The large radius coved corners offer easy cleaning and maintenance while providing optimal air circulation.

Anti Spill Shelves

As you pull the shelves out, BEING’s anti-inclination and shelf locking feature lock them in place when reaching halfway, eliminating any shelf tilting and experiment or sample loss, minimizing accidents, and protecting the operator.

Energy Efficient and Long Lasting

The insulation and NEW silicone door seal minimize heat loss by 20%, reduce thermal power by 25%, and prolong the heating elements’ life compared with traditional equipment.

The fan power adjustment on the BOF models improves overall equipment efficiency (OEE) and increases motor service life by up to 30%.

Space Saving Stackability

At the recommendation of our customers, we have designed the BOF-50, BOF-120, BON-50, and BON-115 models to be stackable to save space. Indentations stamped into each unit’s sheet metal provide easy alignment of another oven and ensure the top oven doesn’t move. The feet are height-adjustable to level the units, front to back and side to side.

TEMPERATURE SPECIFICATIONS

Even, stable and precise temperature control

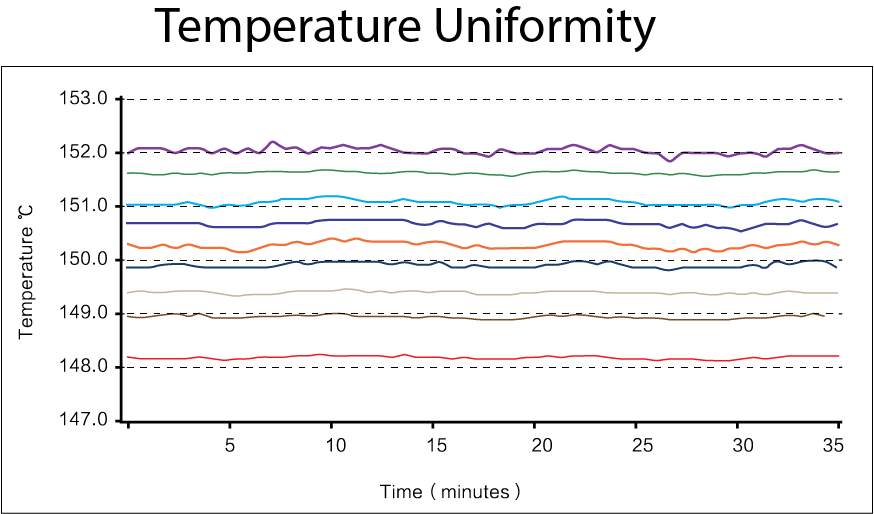

The drying chamber’s temperature uniformity enables all samples to be heated evenly.

BON series: ≤±3.0oC

Note: The stability and uniformity are measured at steady-state.

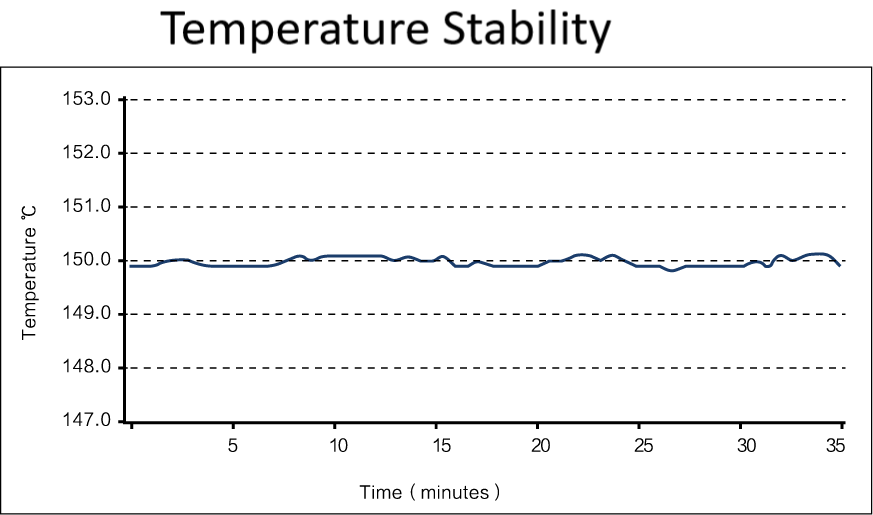

The drying chamber’s temperature stability of ±0.5oC at 100oC ensures experiment stability.

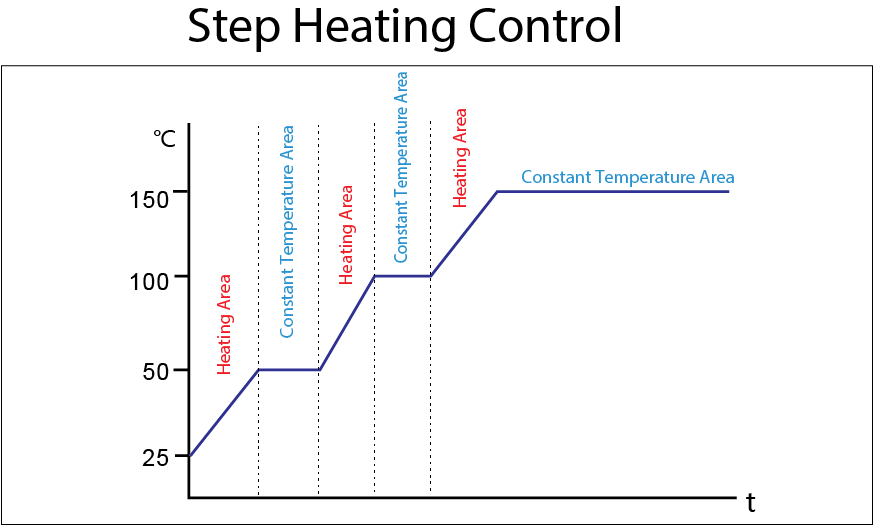

In program control mode, the controller allows the operator to set up step heating control.

QUALITY

Committed to exceeding customer expectations.

ISO 9001

CE

CSA

ETL

BEING is committed to providing users with intelligent, professional, and intuitive laboratory equipment that modern laboratories require. To that end, the BOF and BON Series ovens are designed, manufactured, and tested to the DIN 12880-2007 standard. And they conform to ISO9001 quality standards, and our products are certified by CE, CSE, UL, and ETL.

VALUE

The combination of selection, specifications, features, quality, and being economically priced makes BEING BOF and BON ovens the smart choice — and a valuable asset in your lab.